FQC

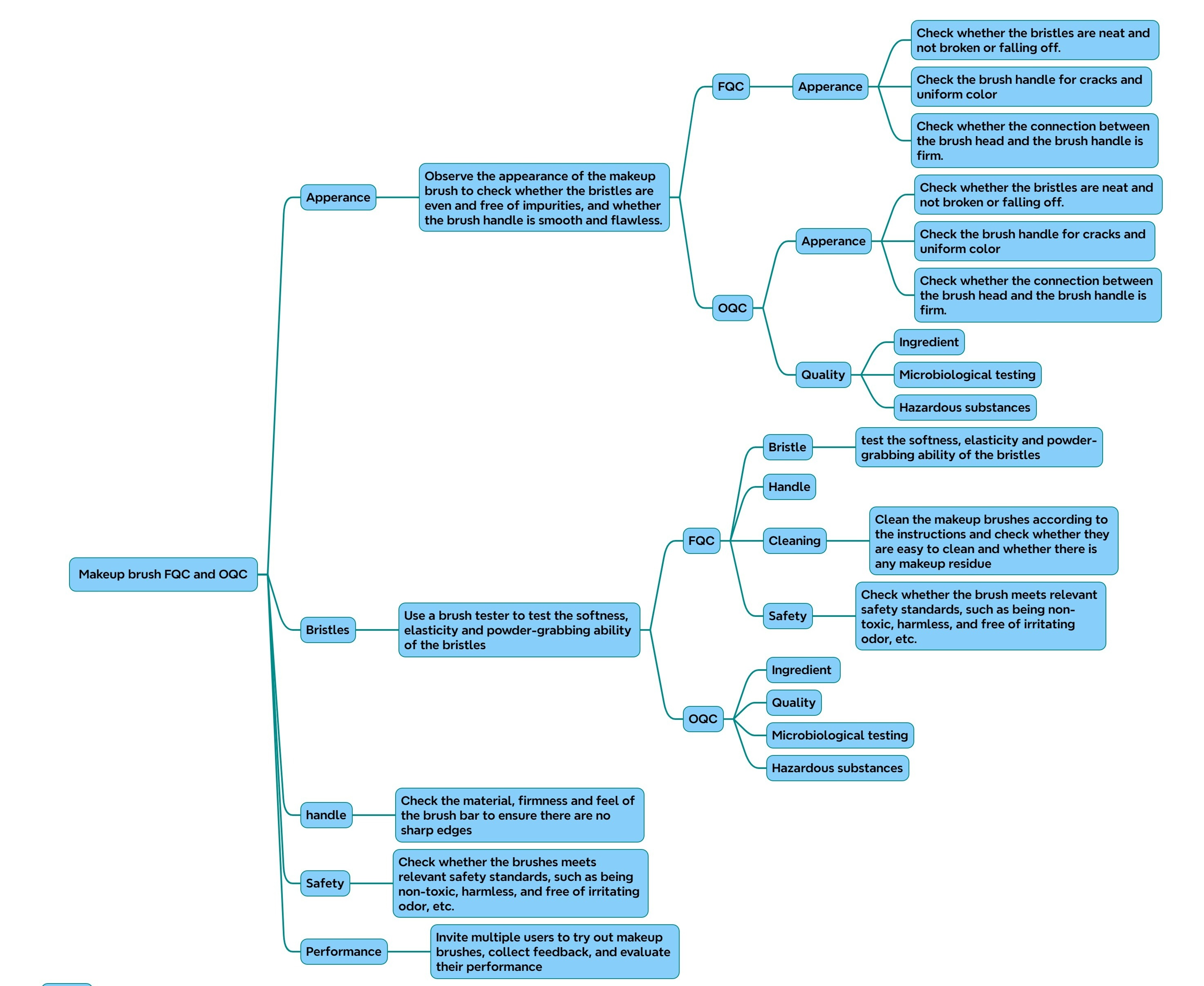

Appearance inspection

- Bristles:bristle arrangement, uniformity, purities or breaks, color consistency

- Brush handle: surface smoothness, no sharp edges or flaws.

- No glue residue, clear logo printing.

- Tools: LED magnifier (20 times), colorimeter (ΔE<1.5).

Functional test

- Hair loss rate: brush 50 times on clean white paper, ≤3 hairs lost.

- Elastic recovery: The bristles recover more than 90% of their original shape within 1 second after being flattened.

- Powder pickup capacity: dip in calibration powder (such as talcum powder), weigh and compare the difference before and after dipping (need ≥0.5g).

Dimension and structure

- Dimensional tolerances of brush handle length, diameter, etc.;

- Connection firmness between brush head and brush handle (through pull-out force test).

Safety testing

- Chemical safety: tested by a third party for heavy metals (lead, arsenic, etc.) and phthalates (compliant with EU REACH regulations).

- Physical safety: sharp edge test (Rohs standard), bristle tip passivation (bristle tip curvature radius under a microscope > 0.1mm).

Packaging

- Inner packaging: dust bag/box sealing, moisture-proof agent (humidity <30%), no printing errors.

- Outer packaging: color box compression test (bearing 50kg without deformation), barcode scan rate 100%.

2. OQC inspection

Packaging integrity

The outer box is intact, the inner packaging is sealed and the accessories are complete (such as dust bags, instructions, etc.).

Batch sampling

Sampling according to AQL standards, focusing on expired products in stock (if more than 3 months, stricter inspection is required).

Document

Check whether the shipping documents (such as quality inspection reports, compliance certificates, packing lists) are complete.

Labels and compliance

The outer box label information (such as batch number, production date) is consistent with the order;

Comply with target market regulations (such as FDA, REACH, etc.).

Function retesting

Randomly sample and retest key performance (such as powder grabbing ability, safety).

3. Differences of FQC and OQC

- FQC focuses on quality control at the end of the production process and must cover all types of product defects;

- OQC focuses on risk control before shipment, focusing on quality problems that may arise during packaging, documents and inventory;

Batch management: Keep 5-10 samples per batch and keep them for 1 year for future reference.

Through the above process, the yield rate of makeup brushes can be effectively controlled (target ≥98.5%), while meeting the stringent requirements of high-end customers (such as professional makeup brands).

Kingyin is a professional Chinese makeup brush factory, with more than 15 years experience in makeup brush production and custom makeup brushes & OEM makeup brushes for worldwide customers and brands.

Kingyin has passed ISO9001, ISO14001, GMP,C-TPAT, FDA/ISO22716, BSCI and SEDEX/SMETA factory audit; with standard workshop, strict quality control and management system,which can ensure makeup brush production and quality.